Coil Binding

Spiral Coil Binding Overview

Transcript:

Welcome to MyBinding video. This video is designed to give you an overview of spiral coil binding. Coil binding is very versatile and very popular. It's secure and can be used with small and large documents. To give you an idea of range, a small coil, a quarter-inch coil, can handle up to 30 sheets, while a 2-inch large coil can handle up to 440 sheets, and there are plenty of colors to choose from. On our website, you'll find there's lots of different colors and options you can look for. There's 3:1 and 5:1 pitch. The difference in these pitches are how many holes are punched per inch on this...

Read More

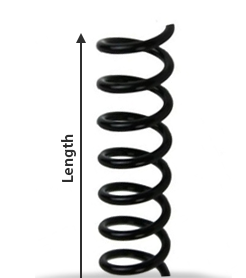

Welcome to MyBinding video. This video is designed to give you an overview of spiral coil binding. Coil binding is very versatile and very popular. It's secure and can be used with small and large documents. To give you an idea of range, a small coil, a quarter-inch coil, can handle up to 30 sheets, while a 2-inch large coil can handle up to 440 sheets, and there are plenty of colors to choose from. On our website, you'll find there's lots of different colors and options you can look for. There's 3:1 and 5:1 pitch. The difference in these pitches are how many holes are punched per inch on this bind and corresponds with the size coil that you need. As you can see, there are plenty of colors and materials to choose from. There's also the option of turbo coil, which is a much stiffer coil designed especially for large books. But it too has a different pitch and needs a specific punch pattern. Now that you have an idea of the coils themselves, let's take a look at the systems and machines that they work on. We'll use the OfficePro 46-E as a way of looking at all the parts. First of all, side margin control. This guides your paper in so that all punches are consistent throughout your entire project. Almost every machine has this. Inserting the spiral coil onto the spine of the book is the most time consuming process, and some machines have a built-in coil inserter to make that easier. It's a rubberized wheel setup that drives the coil all the way down the spine. The final and finishing phase of coil binding is crimping off the ends of the coil. The most common way to do this is with coil crimping pliers. It cuts and crimps the end of the coil. There are machines in the market that can do this process for you, which may be a great idea if you have a lot of books to bind. The variety of machines and systems out there is vast. Some are small and designed for personal or home use and may even contain a small coil inserter. The punching is often done by hand and runs about $100 or $200. Mid-sized machines are built for offices or those who have to do quite a bit of binding. These are a few hundred dollars but they are built to last and process many books for a long time. And extra-heavy stackable modular units are built really for a lot of work and are a thousand dollars and more. So there it is. That is spiral coil binding as an overview. For more how-tos, demos and reviews, checkout MyBinding.com.